Geocell Products

Leading Manufacturers, Exporters, Wholesaler, Retailer, Importer of Channel Protection Geocell, Earth Retention Geocell, HDPE Cellfield, LDPE Cellfield, Load Support Geocell and Slope Protection Geocell from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Type | Geocells |

| Material | HDPE |

| Thickness | 1.5-2mm |

| Application | Erosion Control, Slope/Channel Protection |

| Color | Black, Grey, Etc |

| Pattern | Non Perforated |

| Country of Origin | India |

| Height | 50-300mm |

| Surface | smooth or textured |

| Carbon Black: | Min 1.5% |

| Welding Spacing | 220-1600mm |

| Usage | To the imporement of shallow river way. |

| Payment Terms | T/T, Western Union |

Preferred Buyer From

| Location | Worldwide |

- Geocell system provides a wide variety of economical, flexible protection treatments for open channels and hydraulic structures. The system provides stability and protection of channels exposed to erosive conditions ranging from low-to- high flows either intermittent or continuous.

- Geocell can be used for channel and shoreline protection and on scour aprons, boat ramps and spillways, geocell avoids the need to install costly load support structures.

Typical Applications

- Swales and drainage ditches

- Stormwater diversion or containment

- Process water channels or containment

- Spillways / Down chutes / drop structures

- Culvert outfalls

- intermittent of continous / low-to-high flow channels.

Subgrade Preparation

- Excavate and shape foundation soils.

- Insatll a geotextile underlayer on prepared surfaces.

- If required, install geogrid underlayer on prepared Surfaces. Geocell panel placement and anchorage.

- Subject to site requirement, generally follow the sloppe protection installation method or earth retention installtion method.

Infill Material

- Place chosen infill material in expanded cells

- Limit drop height to a maximum of 1m to avoid damage or displacement of the cell walls.

- Compact infill matetial per engineer's specification.

Infill materials, subject to site conditions, include :

- Top soil for low to moderate and intermittent flow conditions.

- Granular materials including gravel and concrete for channels subject to severe hydraulic and mechanical stresses.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Color | Black, etc |

| Advantage | Easy to Operate |

| Performance | Optimum |

| Quality | Premium Quality |

| Benefit | Excellent Result & Highly effective |

| Features | Long functional life |

Preferred Buyer From

| Location | Worldwide |

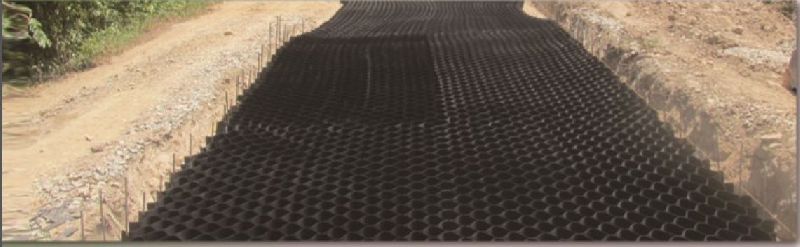

The Geocell geosynthetic cellular confinement system is a matrix of lightweight, expandable and flexible thermoplastic strips that are Ultrasonically bonded to form a strong, dimensionally stable and inert honeycomb structure Forms a long lasting structurall Barrier.

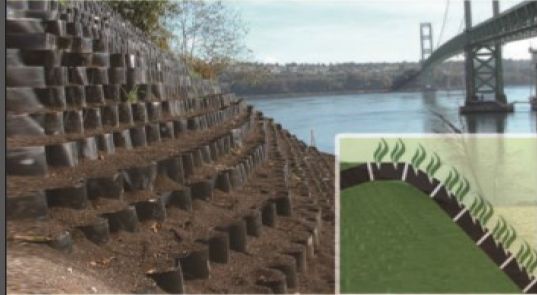

The Geocell System, when layered, becomes an economical lretaining wall system meeting all project-specific structural requirements. The system allows for contruction flexibility and provides aesthetics through a completely vegetated face. Horizontal terraces are formed where vegetation can flourish in the exposed outer cell infill. The system captures rainwater and controls groundwater evaporation, creating a more natural environment for vegetation.

Typical Applications

- Bioengineered walls

- Steepened embankments

- Dike and levee protections

- Culvert headwalls

- Landscape development walls

- Vegetated channel structures sound barries.

Subgrade Preparartion

Excavate and shape foundation soils.

Ensure foundation soil meets minimum strength requirements through proof rolling or other conventional mehtod. It unacceptable foundation soils are encountered, excavate and replace with suitable quality material.

Separation Layer and Base Materials Installation

- When separation between subgrade soil and infill material is required, place geotextile over subgrade.

- If additonal base materials or engineered soils are requierd between separation geotextile and geocell, install the appropriate depth and compact to a minimum 95 percent standard proctor or 90-92 percent modified proctor test -Dependent upon locale and soil confitions.

Geocell Panel Placement and Connection

- Position and expand geocell panels to the appropriate dimensions. Hold individual panels in their expanded positions with rebar J-Pins or wooden stakes. Join panels using traditional Stapling methods or connecting studs.

- Confirm each geocell paenl is expanded uniformly and correctly aligned. Nest panels along each joint to ensure adjacent geocell panels are flush at joint and adjoining cell are fully anchored. Alternate the installation of rebar J-Pins or wooden stakes to ensure each panel is Stable.

- Install rebar fixing or wooden stakes along the joint of each panel in every other perimeter cell to hld the geocell panels stable during infill. Alternate the installtion of rebar fixing pins or wooden stakes to ensure each panel is stable.

Exposed Aggregate or Engineered Infill

- Fill geocell with specified aggregate material progressively from front to back. Do not use an infill material with particle sizes greater than 65 mm.

- Overfill cells to a depth of approximately 50mm and level for exposed aggregate surfaces. Maintain the 50mm wear surface over geocell panels to prevent wear to the cell walls.

- Compact infill to a minimum of 95 percent Standard Proctor or 90-92 percent Modified Proctor test.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Color | White |

| Material | HDPE |

| Height | Upto 200 mm |

| Thickness | 2 - 4 mm, etc |

| Cell Depth | 75 mm |

| Features | Long functional life |

Preferred Buyer From

| Location | Worldwide |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Thickness | 220 300 micron , etc |

| Color | White transparent |

| Features | Wear resistant , Light in weight |

| Material | HDPE |

| Width | 2.75 m to3.75 m, etc |

| Height | 75 to 250 mm, etc |

| Payment Terms | T/T |

Preferred Buyer From

| Location | Worldwide |

We are the only manufacturers of 220 Microns thick 150x150x100 mm & 150x150x150 mm dimentions Concrete filled Geocells. Specially Recommended for fast installation of PMGSY & Rural roads.Concrete cell field for PMGSY as per the specification by GKN of PMGSY given by government.

150x150mm with height 100mm containing 220 microns

Also 75mm height available With this cell we can increase stability of road.

We provide quality product. our product is selected in any test related toPMGSY..

100% genuine product & on time delivery

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Feature | Lightweight, & Strong |

| Color | Black, etc |

| Usage | A Foundation reinforcement mat for improvement of load bearing capacities of weak soilsities of weak |

| Performance | Optimum |

| Features | Long functional life |

| Advantage | Easy to Operate |

Preferred Buyer From

| Location | Worldwide |

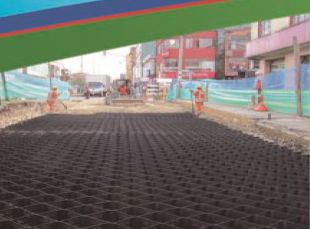

The Geocell load support system stabilizes the selected infill and provides ecomincal solutions to unstable surface or base problems in three key ares :

- A Load distribution system over weak soils

- Base stabilization for paved surfaces

- surface stabilization for unpaved surfaces.

Subgrade Preparation

- Excavate and shape foundation soils.

- Ensure foundation soil meets minimum strength requirements through proof or other conventional method. If unacceptable foundation soils are encountered, excavate and replace with suitable quality material.

Separation Layer and Base Materials Installation

- When separation between subgrade soil and infill material is required, place geotextile over subgrade.

- If additonal base materials or engineered soils are requierd between separation geotextile and geocell, install the appropriate depth and compact to a minimum 95 percent standard proctor or 90-92 percent modified proctor test.

Geocell Panel Placement and Connection

- Position and expand geocell panels to the appropriate dimensions. Hold individual panels in their expanded positions with rebar J-Pins or wooden stakes. Join panels using traditional Stapling methods or connecting studs.

- Confirm each geocell paenl is expanded uniformly and correctly aligned. Nest panels along each joint to ensure adjacent geocell panels are flush at joint and adjoining cell are fully anchored. Alternate the installation of rebar J-Pins or wooden stakes to ensure each panel is Stable.

- Install rebar fixing or wooden stakes along the joint of each panel in every other perimeter cell to hld the geocell panels stable during infill. Alternate the installtion of rebar fixing pins or wooden stakes to ensure each panel is stable.

Exposed Aggregate or Engineered Infill

- Fill geocell with specified aggregate material progressively from front to back. Do not use an infill material with particle sizes greater than 65 mm.

- Overfill cells to a depth of approximately 50mm and level for exposed aggregate surfaces. Maintain the 50mm wear surface over geocell panels to prevent wear to the cell walls.

- Compact infill to a minimum of 95 percent Standard Proctor or 90-92 percent Modified Proctor test.

Base Stabilisation

- Overfill geocell to a depth of 25mm and compact to a minimum of 95 percent Standard Proctor or 90-92 percent Modified Proctor test.

- The wearing course may consist of asphalt/concrete/paver stones/gravel or grass stabilizer or other as specified. Install per engineer's specifications.

Details

- Site Access Roads.

- Permeable, Load-supporting Surfaces.

- Roadway Shoulders.

- Intermodal /port Facilities.

- Transportation/storage Yards.

- Stabilized Drainage Layer.

- Trails And Walkways.

- Track Ballast And Subballast Structures.

- Stabilized Base For Asphalt Or Modular Block Pavements.

- Boat Ramps / low Water Crossings.

- Foundation Mattresses And Pipeline Protection.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Color | Grey, etc |

| Usage | Preventing run-off and soil erosion |

| Feature | Preserving the soil structure |

| Application | Enabling flow of water, nutrients and soil organisms |

| Advantage | Easy to Operate |

| Performance | Optimum |

Preferred Buyer From

| Location | Worldwide |

The Geocell slope and shoreline protection system confines. reinforces and restrains the upper soil layer and infill controlling down-slope movement and slippage due to hydrodynamic and gravitational forces.

- Provides effective slope protection and structural confinement of topsoil/vegetation and granular materials suchas send, gravel and larger rock or stone.

- Becomes a flexible concrete mat with built-in expansion joints when cells are infilled with concrete.

- Creates additional stability by integrating tendons on steeper slopes and shoreline embankments or when a geomembrane or hard soil/rock surface prevents anchoring with stakes.

- Allows embankments to be steeper than when unconfined, reducing use of valuable land space.

Subgrade Preparation

- Excavate and shape foundation soils.

- Insatll a geotextile underlayer on prepared surfaces.

- If required, install geogrid underlayer on prepared Surfaces.

Geocell Panel placement and tendon fixing

- First calculate the length of the slope in order to determine the number of panels required and the length of your tendons.

- Allow approx. 200 mm for each securing anchor to be tied off plus an additional 1 m per tendon run for anchor placement. The number of securing anchors and tendons used will depend on the gradient of the slope. (i.e the steeper the slope the more anchors and tendons required.)

- Position collapsed geocell panels at crest of slope. Secure tendons at the crest of the slope with galvanized anchors.

- Feed the tendon through the first collapsed panel. Secure subsequent panel / s with connecting studs and continue to feed tendon through each individual collapsed panel.

- Once the tendon has been fed through all panels, fully extend tendon down the slopw

- Drive a rebar J- Pin trough every perimeter cell along the crest of the slope to secure the top edge of the geocell panels in place.

Begin to expand the panels / s down the slope, securing the panels as you go with J-pins (according to suggested laying pattern) in their fully expanded postion. - Once the entire matrix has been positioned, return to tendons working from the crest down, drive in anchors tight against the cell walls in line with tendon.

- Take the slack from the tendon and wrap it aroung the central column 3 or 4 times before repeating the process on the next anchor.

- Tie off the tendon securely on the last anchor at the bottom of the slop, drive a rebar-J-Pin Through every perimeter cell along the final row.

Infill Material:

- Infill expanded panels with chosen material working from the bottom of the slope up towards. the crest (for less exposed slopes seeded top-soil is suggested, adding small shrubs will give improved protection).

- Limit Drop height to a maximum of 1 m to avoid damage or displacement of the cell walls.

- Compact infill material per engineer's specification.

Typical applications

- Cut or fill embankment slopes

- Shoreline revertments

- Abutment protection

- Stormwater / Waste water lagoons

- Containment dikes and levees

- geomembrane protection

- Landfill linings and covers

- Dam faces and spilways